In today’s world, we are surrounded by many of these electronic components and we are so dependent on them that it would be very difficult to live without them. It is difficult to conceive what the emerging technological age would be like without the invention of chips. So we can conclude that the chip is one of the most important innovations of our time. Let us know the important point for processing this chip.

Chip concept

These chips are primarily used for military purposes, but they have quickly gained popularity in the domestic and medical sectors. A chip is a container for an IC (integrated circuit) that is formed from a wafer and is usually used in electronic devices like computers. The chip integrates the electronic components we see everywhere, such as resistors and capacitors, in addition to the circuits made up of them, into an individual small unit. Chip processing is identical to putting together such a home with blocks.

Fig 1. 8085 microprocessor board

The wafer is applied as the structure first, after which you can construct your desired shape by stacking layer after layer. The chip is an amazingly precise piece of equipment, featuring it is so small that it is measured in nanometers such as the central component of a regular Intel Core CPU is approximately the size of a man fingertip, but somehow it contains billions, or tens of billions, of transistors. There are several different varieties of chips. A chipset is a collection of linked chips. They are interconnected and can play a more significant role when combined. Fig. 1 shows an 8085 microprocessor consisting of different types of IC.

Chip Advancement

Modern microchip design concepts, along with enhanced EDA tools, have made chip design more accessible and dependable than ever before.

Within the last decade, the physical dimensions of transistors have shrunk dramatically. This developed in both very big chips and low-voltage chip architectures, which indicates that processors consume very little energy, even a few microwatts. This enabled excellent chip scalability in a variety of sectors and industries, both in terms of semiconductor size and market participation.

The integration of co-simulation (software and hardware) design is another key development in chip design. As a result, the entire algorithm is separated into two sub-blocks:

- Submodules that require heavy calculation are moved to hardware, such as chips;

- Complex modules that rely on data and are engaged in decision making are handled by software. The illustration below demonstrates how the design process is separated into several subgroups.

Ultimately, IP cores are critical for the chip design process. When a developer needs to execute a complicated design, he can save time and decrease associated risks by using IP cores.

Chip categorization

Before we see the actual designing process, let us see some of the types in which chips are categorised.

- ASIC: An Application-Specific Integrated Circuit is an integrated circuit that is designed specifically for a certain application or function. An ASIC may be found in practically any electronic device, and its applications vary from specialised picture rendering to sound conversion. Because ASICs are custom-made, they can only be utilised by the firm that created them, making them private technology.

- ASSP: Application-specific standard product (ASSP) design and implementation are identical to ASIC. The key contrast is that the ASSP is a more adaptable device that may be used in a variety of system design studios.

- SOC: System on Chip is an abbreviation for System on Chip. A single cannot be labelled a system since it is a system. A system can only be defined as a group of people working together.

- FPGA: A field-programmable gate array (FPGA) is a semiconductor device that is made up of a matrix of customizable logic blocks (CLB) linked together via programmable interconnects.

- Microprocessor: It is also demonstrated as μP or MPU. A microprocessor is an integrated circuit that simply includes a CPU. It has no memory (RAM, ROM, etc.) or any passive components.

- Microcontroller: It is also demonstrated as μC or MCU. A microcontroller is an integrated circuit that contains a CPU, memory (RAM, ROM, etc.), and various components.

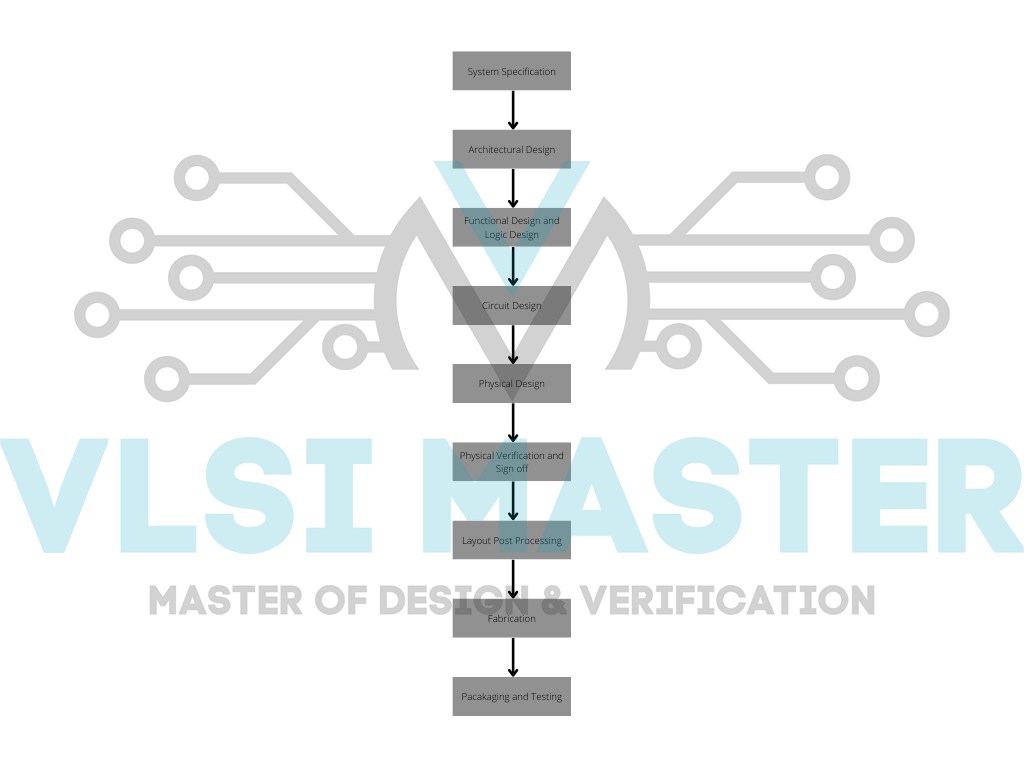

Flow of Chip Design

The chip design flow is quite similar to that of the FPGA design flow. The only exception is that chips are made or fabricated after the design has been finished. The chip design flow is depicted in the chart below.

Fig 2. Flow chart of Chip Design

System Specifications

The initial and most crucial phase in the chip design process is to define and create the system specification.

Architecture Design

The next phase is to design the system’s architecture, which determines which blocks will be employed and at what hierarchical level the system will work.

Basic Logic Design

Following the design of the architecture, the fundamental logic system is created. This schematic can be created with help of DSCH software programme which is essentially software for constructing digital schematic circuits. This programme for microwind simulation allows users to model and design integrated circuits at the physical description level as

Verification and Layout Post Processing

Once the system’s schematic design is complete, the subsequent stage is to test the system’s functionality. This may be accomplished by running simulations in the same tool. This stage is critical since it allows for first verification and allows any issues with system operation to be addressed right away. The following and most crucial stage is to transfer the system to a physical level. The physical layout must be reviewed before proceeding to the fabrication plant.

Fabrication and Final Testing

The ultimate stage is to create the actual layout design. All libraries and layer information are given by the foundry that will produce the chip while creating the system on the tools. The ultimate testing is done on circuitry, which requires the creation of a prototype PCB on which the chip is attached, as well as the integration of all essential interfaces for testing.

Now that you know so much, there must be a question in your mind about how all this will be designed? So many companies come for this, which aids in its creation. We will study this further. Mainly there are two famous contestant which offer you chip design tool market i.e. Siemens and Cadence.

And at last a few questions which we can answer after reading this blog about the chip design process.

- What are Chips in IC?

- How do Chips Evolve?

- What are the types of Chips that are used frequently?

- What are the major steps involved in the designing process of Chips?